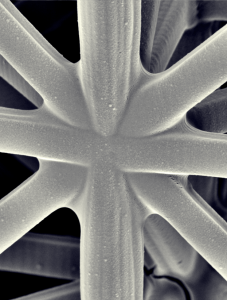

Three-dimensional (3D) printing of silica glass is dominated by techniques that rely on traditional particle sintering. At the nanoscale, this limits their adoption within microsystem technology, which prevents technological breakthroughs. We introduce the sinterless, two-photon polymerization 3D printing of free-form fused silica nanostructures from a polyhedral oligomeric silsesquioxane (POSS) resin. Contrary to particle-loaded sacrificial binders, our POSS resin itself constitutes a continuous silicon-oxygen molecular network that forms transparent fused silica at only 650°C. This temperature is 500°C lower than the sintering temperatures for fusing discrete silica particles to a continuum, which brings silica 3D printing below the melting points of essential microsystem materials. Simultaneously, we achieve a fourfold resolution enhancement, which enables visible light nanophotonics. By demonstrating excellent optical quality, mechanical resilience, ease of processing, and coverable size scale, our material sets a benchmark for micro– and nano–3D printing of inorganic solids.

KIT News Physics Today Optics & Photonics News Frankfurter Allgemeine Zeitung VDI Podcast

Architected metals and ceramics with nanoscale cellular designs, e.g., nanolattices, are currently subject of extensive investigation. By harnessing extreme material size effects, nanolattices demonstrated classically inaccessible properties at low density, with exceptional potential for superior lightweight materials. This study expands the concept of nanoarchitecture to dense metal/ceramic composites, presenting co-continuous architectures of three-dimensional printed pyrolytic carbon shell reinforcements and electrodeposited nickel matrices. We demonstrate ductile compressive deformability with elongated ultrahigh strength plateaus, resulting in an extremely high combination of compressive strength and strain energy absorption. Simultaneously, property-to-weight ratios outperform those of lightweight nanolattices. Superior to cellular nanoarchitectures, interpenetrating nanocomposites may combine multiple size-dependent characteristics, whether mechanical or functional, which are radically antagonistic in existing materials. This provides a pathway toward previously unobtainable multifunctionality, extending far beyond lightweight structure applications.

UCI News

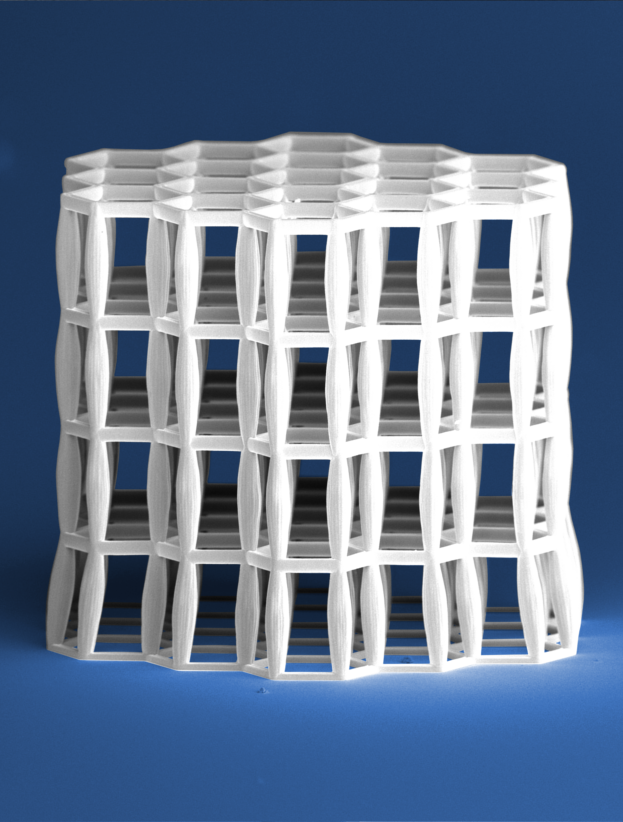

Failure of materials and structures is inherently linked to localized mechanisms, from shear banding in metals, to crack propagation in ceramics and collapse of space‐trusses after buckling of individual struts. In lightweight structures, localized deformation causes catastrophic failure, limiting their application to small strain regimes. To ensure robustness under real‐world nonlinear loading scenarios, overdesigned linear‐elastic constructions are adopted. Here, the concept of delocalized deformation as a pathway to failure‐resistant structures and materials is introduced. Space‐tileable tensegrity metamaterials achieving delocalized deformation via the discontinuity of their compression members are presented. Unprecedented failure resistance is shown, with up to 25‐fold enhancement in deformability and orders of magnitude increased energy absorption capability without failure over same‐strength state‐of‐the‐art lattice architectures. This study provides important groundwork for design of superior engineering systems, from reusable impact protection systems to adaptive load‐bearing structures.

UCI News GaTech News National Science Foundation AZOMaterials Society of Chemical Industry

3D-printed nano-architected ceramic metamaterials currently emerge as a class of lightweight materials with exceptional strength and stiffness. However, their application is hampered by the lack of knowledge on their mechanical reliability. Characteristics like the fracture strength and their dependency on environmental conditions are unknown. We herein present and discuss a nanoindentation pillar splitting method to measure fracture toughness, elastic modulus, and hardness of 3D-printed nano-ceramics. We show that two photon polymerization-derived pyrolytic carbon achieves improved fracture toughness over macroscopic forms of vitreous carbon, with values up to 3.1 MPam0.5. However, experiments at different humidity levels reveal that only few, nanometer-sized, surface cavities can cause embrittlement from liquid diffusion, which promotes earlier crack propagation. While comparable effects are less relevant in macro-size ceramics, this study demonstrates that reliability and durability of micro- and nano-architected ceramic metamaterials and devices requires toughening design approaches that focus on size-dependent surface effects.

Two-photon polymerization direct laser writing (TPP-DLW) is one of the most versatile technologies to additively manufacture complex parts with nanoscale resolution. However, the wide range of mechanical properties that results from the chosen combination of multiple process parameters imposes an obstacle to its widespread use. Here we introduce a thermal post-curing route as an effective and simple method to increase the mechanical properties of acrylate-based TPP-DLW-derived parts by 20-250% and to largely eliminate the characteristic coupling of processing parameters, material properties and part functionality. We identify the underlying mechanism of the property enhancement as a self-initiated thermal curing reaction, which robustly facilitates the high property reproducibility that is essential for any application of TPP-DLW.

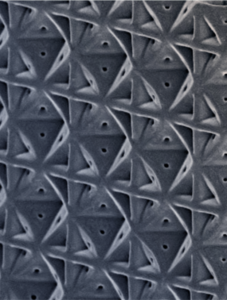

Here, we present a new class of nanolattices, constructed from closed-cell plate-architectures. These plate-nanolattices are shown to reach the Hashin-Shtrikman and Suquet upper bounds, via in situ mechanical compression, nano-computed tomography and micro-Raman spectroscopy. Showing specific strengths surpassing those of bulk diamond and average performance improvements up to 639% over the best existing nanolattices, this study provides detailed experimental evidence of plate architectures as a superior metamaterial topology.

Learn more about plate-nanolattices on Seeker!

UCI News UCSB Current Tech Times Society of Chemical Industry Phys.org Chemie.de

*A.G.I. & J.B. contributed equally

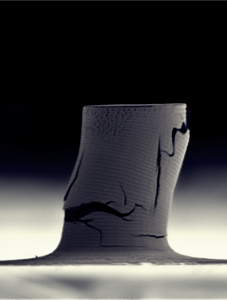

Nanolattices are promoted as next‐generation multifunctional high‐performance materials, but their mechanical response is limited to extreme strength yet brittleness, or extreme deformability but low strength and stiffness. Ideal impact protection systems require high‐stress plateaus over long deformation ranges. Here we introduce glassy carbon nanoarchitectures with spinodal shell topology, showing non-catastrophic deformability up to 80% strain and order of magnitude higher energy absorption capability than any reported nano-, micro- and macro-architected and monolithic material. At the same time, strength and stiffness are on par with the most advanced, yet brittle nanolattices, demonstrating true multifunctionality. Finite element simulations show that optimized shell thickness‐to‐curvature‐radius ratios suppress catastrophic crack propagation.

UCI News Science Magazine

Ceramics would be ideal materials if their brittleness could be overcome. While ductility and extraordinary strength have been reported at the nanoscale, they both rapidly disappear when samples reach micrometer dimensions; and manufacturing is limited to elaborate purely scientific approaches. We present a route to additively manufacture ductile, ultrastrong silicon oxycarbide (SiOC) via two-photon polymerization of a preceramic resin and pyrolysis. We 3D-print micropillars and nanoarchitectures with feature sizes down to ∼200nm. Independent of size, SiOC micropillars deform plastically with strains up to 25% and strengths >7 GPa, across the entire range of examined diameters (1–20μm). Our findings demonstrate fabrication of ductile, ultrastrong ceramics at unprecedented scales, potentially enabling manufacturing of millimeter-size engineering systems.

MRS Bulletin Chemical & Engineering News Cell Press Preview

Two‐photon polymerization (TPP) is the most promising technology for additive manufacturing of complex parts with nanoscale features, and could dramatically accelerate the development of engineering micro/nanosystems. However, a major obstacle to TPP's industrial adoption is the lack of systematic data on material properties and limited knowledge on their correlation with processing parameters. We establish these correlations for the acrylate‐based resin IP‐Dip over a large range of process parameters and length scales ranging from nanometers to centimeters. Universal relations between mechanical properties and process parameters are identified, which enable the tailoring of the material strength and stiffness over half an order of magnitude from rubbery soft to hard and strong. With a threshold‐based model, the mechanical properties of the material can be accurately captured as a function of the applied TPP parameters, laying the foundation for a universal quantitative predictability of TPP with programmable mechanical properties.

The mechanical response of cellular materials with spinodal topologies is numerically and experimentally investigated. Spinodal microstructures are generated by the numerical solution of the Cahn-Hilliard equation. Two different topologies are investigated: ‘solid models,’ where one of the two phases is modeled as a solid material and the remaining volume is void space; and ‘shell models,’ where the interface between the two phases is assumed to be a solid shell, with the rest of the volume modeled as void space. For a wide range of relative densities and spinodal characteristic feature sizes finite element models are generated and the uniaxial compressive stiffness and strength are extracted. We show that shell spinodal models in the density range of 0.01–1% are exceptionally stiff, strong and remarkably imperfection insensitive. These findings are verified experimentally by in-situ uniaxial compression of polymeric samples printed at the microscale by Direct Laser Writing (DLW). At low relative densities, the strength and stiffness of shell spinodal models outperform those of most lattice materials and approach theoretical bounds for isotropic cellular materials. Most importantly, these materials can be produced by self-assembly techniques over a range of length scales, providing unique scalability.

By designing advantageous cellular geometries and combining the material size effects at the nanoscale, lightweight hybrid microarchitectured materials with tailored structural properties are achieved. However, few studies have examined the properties of composite structures with metal coatings. Here we use 3D laser lithography and electroless deposition of an amorphous layer of nickel-boron (NiB) coating to produce metal/polymer hybrid structures. The mechanical response of microarchitectured structures is investigated with an emphasis on the effects of the architecture and the amorphous NiB thickness on their deformation mechanisms and energy absorption capability. Microcompression experiments show an enhancement of the mechanical properties with the NiB thickness, suggesting that the deformation mechanism and the buckling behavior are controlled by the brittle-to-ductile transition in the NiB layer. The energy absorption properties demonstrate the possibility of tuning the energy absorption efficiency with adequate designs.

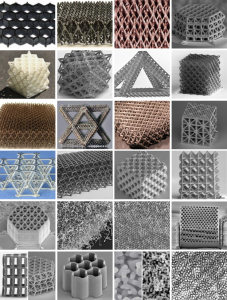

In 1903, Graham Bell developed mechanically robust lattice structures based on triangular cells; which have since found broad application in lightweight design. Over 100 years later, the same principle is used in the fabrication of nanolattice materials, namely lattice structures composed of nanoscale constituents. Taking advantage of the size‐dependent properties typical of nanoparticles, nanowires, and thin films, nanolattices redefine the limits of the accessible material‐property space throughout different disciplines. Herein, the exceptional mechanical performance of nanolattices and their potential for multifunctional applications are examined. The efficient integration of architecture and size‐affected properties is key to further develop nanolattices. The introduction of a hierarchical architecture is an effective tool in enhancing mechanical properties, and the eventual goal of nanolattice design may be to replicate the intricate hierarchies and functionalities observed in biological materials. Additive manufacturing and self‐assembly enable lattice fabrication at the nanoscale; scalability is the current major obstacle to their widespread applications.

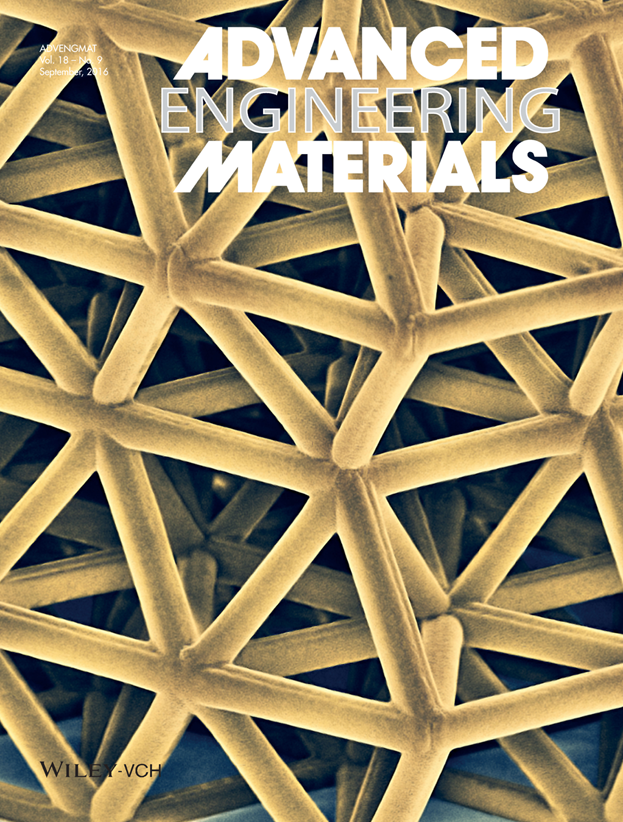

The strength of lightweight mechanical metamaterials, which aim to exploit material-strengthening size effects by their microscale lattice structure, has been limited by the resolution of three-dimensional lithography technologies and their restriction to mainly polymer resins. Here, we demonstrate that pyrolysis of polymeric microlattices can overcome these limitations and create ultra-strong glassy carbon nanolattices with single struts shorter than 1 μm and diameters as small as 200 nm. They represent the smallest lattice structures yet produced—achieved by an 80% shrinkage of the polymer during pyrolysis—and exhibit material strengths of up to 3 GPa, corresponding approximately to the theoretical strength of glassy carbon. The strength-to-density ratios of the nanolattices are six times higher than those of reported microlattices. With a honeycomb topology, effective strengths of 1.2 GPa at 0.6 g cm−3 are achieved. Diamond is the only bulk material with a notably higher strength-to-density ratio.

KIT News Frankfurter Allgemeine Zeitung Physics Today Sci-News Der Standard

Lattice materials are strong yet light. Miniaturizing the pattern size to the micro-scale allows exploiting mechanical size effects. So far, the impact of the lattice size on the strength has not been studied systematically and mechanical characterization has been focused on compression tests only. Here, the strength of polymer–alumina core–shell composite microlattices with different pattern sizes is investigated in compression and tension. The compressive strength increases by a factor of two when the lattice size is scaled down by 50%. With tensile strengths of up to 27 MPa at 0.37 gcm−3, the microlattices outperform all technical foams and most monolithic ceramics. Isotropic strength under tension and compression is found when thickness-dependent notch effects in the alumina shells are considered.

Materials Views

The search for light yet strong materials recently benefited from novel high resolution 3D-printing technologies, which allow for fabricating lightweight porous materials with optimally designed micro-topologies. Architectural design improves mechanical properties significantly compared to stochastic porosity, as in foams. Miniaturization of the architectures offers to exploit material strengthening size-effects occurring at the nanoscale. However, these effects and their interaction with structural behavior are not yet well understood. We present tensile experiments of nanoscale alumina–polymer composite bars and cellular microarchitectures, applying 3D-printed push-to-pull mechanisms. The strength of alumina is found to strongly increase as the material thickness decreases. Below 50 nm thickness a plateau at about 5.5 GPa is reached, which is in the range of the theoretical strength. The characteristic low tensile strength of ceramics and its high variability seem not to hold at the nanoscale. Thus, when designed and fabricated appropriately, microarchitectures will facilitate carrying these size-effects beyond scales in future, allowing the use of ceramic materials far beyond what is possible to date.

Cellular materials with specific 3D microarchitectures achieve outstanding strength-to-weight ratios due to the mechanical size effect and their optimized architecture. Applying 3D direct laser writing and different coating techniques polymer nanocomposites can be fabricated. So far, mainly coatings and techniques were investigated to enhance the mechanical properties. It is the aim of this study to improve the strength of polymer lattices by annealing treatments to the polymer after the laser writing step. We present push-to-pull tensile tests of single struts as well as compression tests of entire truss structures after different annealing temperature–time combinations. Depending on the heat treatment, strength, stiffness and engineering toughness can be optimized for the use in architected materials. We show that the tensile strength of single struts increases by a factor of 10 compared to samples without heat treatment. Simultaneously, the compressive strength of truss structures imroves by a factor of 2.5. Here, failure is induced by stress concentrations at the truss nodes, wherefore the strength gain observed with tensile test bars is not fully exploited.

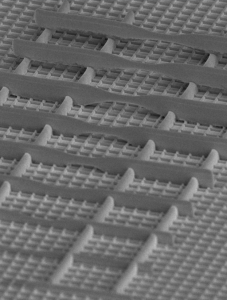

Designing materials with exceptional combinations of properties at low weight is a continuous goal in many industries. Cellular (i.e., porous) materials with one or more phases topologically organized in a precisely designed configuration (often denoted as architected materials, or metamaterials) are excellent candidates to reach combinations of properties that are unattainable by existing monolithic materials. Additive manufacturing techniques are perfectly suited to implement the topological complexity that is often required for optimal performance. As beneficial size effects often arise in mechanical and functional properties as dimensions are shrunk to the nanoscale, 2PP becomes an ideal platform to investigate and ultimately fabricate topologically micro-architected and nano-architected materials with truly unique properties. The chapter reviews some notable features of architected materials, surveys commonly available manufacturing approaches, and presents challenges and opportunities for 2PP fabrication.